dorol and quadropol® Expert Service

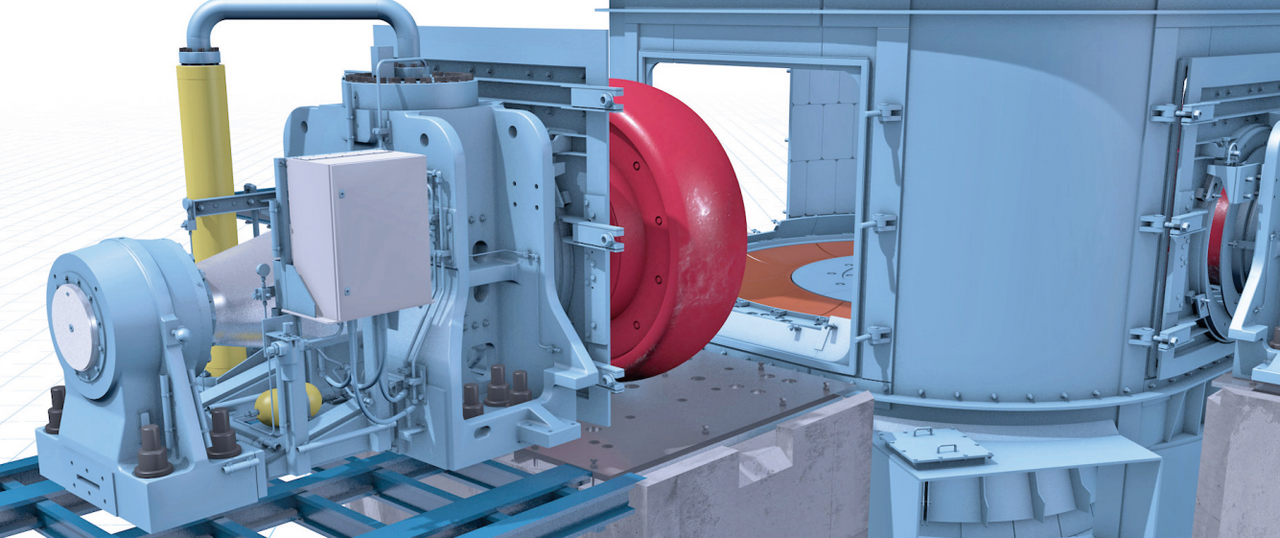

Boost Plant Performance with our dorol and quadropol® Expert Service for Vertical Roller Mills

With decades of experience and numerous successful references, our dorol and quadropol® vertical roller mills have proven their reliability worldwide. However, after many years of operation, some roller mills no longer deliver optimal performance. Reduced throughput can impact the productivity of both upstream and downstream plant sections, while also driving up specific energy consumption. By applying our expertise, we help restore mill efficiency, reduce energy costs, and ensure smooth operation across the entire production process.

Our dorol and quadropol® Expert Service is designed to restore and enhance the performance of your mill through a comprehensive, on-site inspection by our specialists. Experts from process technology, mechanical systems and service analyse the complete mill setup – including the separator, coarse feed valve, fan, cyclone and filters.

We combine precise measurements during operation with detailed inspections during scheduled stoppages. This approach gives us a full picture of both the mechanical condition and the operating parameters. We assess critical factors such as grinding bed depth, false air levels, nozzle ring air velocity, gas flow volumes and wear patterns.

Based on these insights, we identify optimisation potential to improve both performance and availability. Together with you, we create a detailed action plan and implement it directly on site. The result: higher plant availability, increased productivity and lower energy costs.

Thanks to our proven methodology, you can expect measurable results within just one week — typically a 5–25% increase in production and a significant reduction in energy consumption.

Your added value

Your added value

Increase in mill capacity and availability

Minimisation of energy consumption and operating costs

Optimized low vibration mill operation

Increased service life for mechanical elements

Recommendations for further optimisation steps

Advice and training for your personnel

Spare parts recommendations and calculable stocking of spare parts