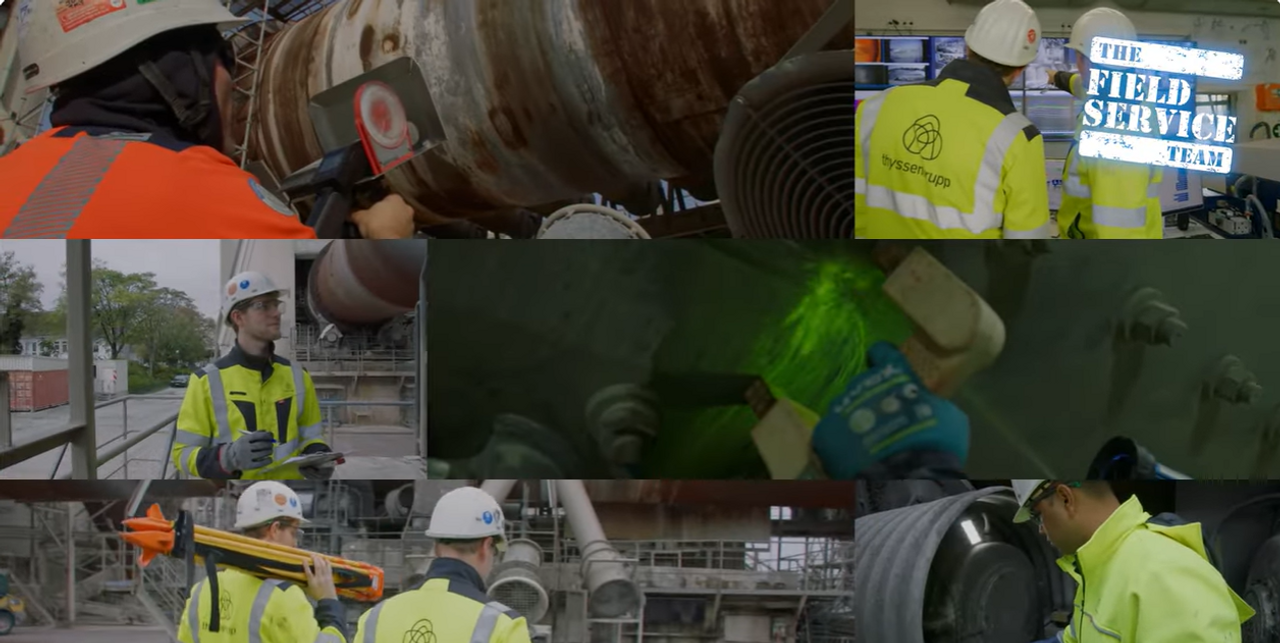

Field & Workshop Services - Increase your plant availability and reduce downtime

Our field & workshop services for your plants

We are your local service partner with plant know-how: With our local service centers, we have established a close-knit global network that is constantly developing. Therefore, we can provide fast, local and comprehensive assistance when it comes to supplying or overhauling strategic spare and wear parts. We also offer field service support, such as ad-hoc repairs, technical assistance, maintenance, inspections and additional services.

Technical inspections and audits for optimizing throughput and ensuring operation

Either by a visual inspection of your machine, if required with additional vibration and temperature analyses, or also by means of measurements through modern scan techniques of your rotary kiln, crusher or mill, our Polysius service experts can detect and eliminate problems early on site before greater damage occurs.

In addition, we provide you with a comprehensive overview of the condition of your plant and give individual recommendations regarding preventive maintenance and modernization. This significantly increases the availability of your machines and components and reduces unplanned downtime.

Because time is money: Reliable shutdown repairs / revisions and support in the event of a breakdown

During a shutdown every minute counts. Therefore, our experts carry out precisely planned repairs within your shutdown schedule. We are also there for you in case of emergency by assisting you in failure identification and ad-hoc repairs, to keep your loss of production as low as possible.

Close to you: Our workshops for overhauling as well as repairing your spare and wear parts

Our Polysius workshop in Beckum as well as our worldwide thyssenkrupp service centers are high-tech workshops specialized on complex repairs in the field of crushing, grinding, pyro processing/ cooling, such as the refurbishment of crushers and HPGR polycom®. In all of the services we offer, our customers benefit from decades of experience gained in the cement industry.

Besides the actual engineering, manufacturing and purchasing, we provide additional services for spare and wear parts, such as assembly supervision, installation, dismantling, refurbishment and replacement - or handling of the complete supply chain.

Success Stories

Success Stories

Improving Cement Plant Efficiency: polscan® Alignment Service in the Philippines

The thyssenkrupp Polysius Service Team in the Asia Pacific region recently was awarded a contract to provide alignment services using polscan® for all three lines of a cement plant in the Philippines. This involves thoroughly measuring and recording the rotary kiln's geometry. The team collaborated closely with the client to customize the polscan® solution according to their needs.

Having polscan® equipment and experts in the Philippines improves flexibility, reduces logistics costs, and saves time in meeting customer requirements.

polscan® - a high-precision opto-electronic measuring method for checking the rotary kiln geometry

Our field service experts around the world provide competent support for various services like drone inspections, poldrive® drive checkups, and polgrind® grinding solutions.

"With our polscan® service, we can detect and correct kiln malfunctions early, resulting in increased rotary kiln availability," says a member of #TheServiceTeam at thyssenkrupp Polysius and supervisor for this service. Since its introduction in 1985, our experts have measured over 2,500 rotary kilns in more than 75 countries. We have stationed measurement systems in various regions to provide local support. This service allows highly accurate, opto-electronic measurement of rotary kilns during operation.

Read the full article on our INSIGHTS blog or download it here!